Hollywood, meets science, meets sport thanks to an innovative research project in the Precinct that is bringing the Gold Coast’s industry strengths together.

Biomechanical engineers at Griffith University’s Centre for Biomedical and Rehabilitation Engineering – with support from the Australian Institute of Sport (AIS) and the Queensland Academy of Sport (QAS) – have turned to film industry 3D animation and visual effects experts to develop a proof of principle of a world-first Digital Athlete.

We take a sneak peek of the process – and watch the completed video below.

The film industry has been animating action with increasing precision and life-like quality over recent decades, building on motion capture technologies that were originally developed by biomechanical engineers.

Ask 20-year veteran of the Gold Coast film industry Duncan Jones of Myriad Studios, and he talks of a constantly innovative and evolving industry from the earliest days of silent movies, always making the unbelievable appear believable in the quest for movie magic.

And now creatives across film and science are combining in a new application of the latest digital technology – the Digital Athlete project brings the two streams of expertise together in the name of sport to create digital twins that are more exact than ever before.

“It’s very complimentary to the work we do, but also different and very exciting,” Duncan Jones says.

“The art of filmmaking is make-believe – nothing is ever real – but the Digital Athlete is blending our technologies with biomechanical science to create something that is entirely realistic.

It’s a fantastic cross-collaboration.”

Having started out specialising in location selection for film sets, Duncan and his team of six have evolved to digitally capture locations in precise detail and create digital doubles of cast, backgrounds and props to support camera alignment and lighting on set, and animation and visual effects in post-production.

He’s worked on well-known Hollywood productions including Thor:Ragnarok, Aquaman and Paramount Pictures’ recent Netflix release Love and Monsters, which received an Academy Awards nomination for visual effects.

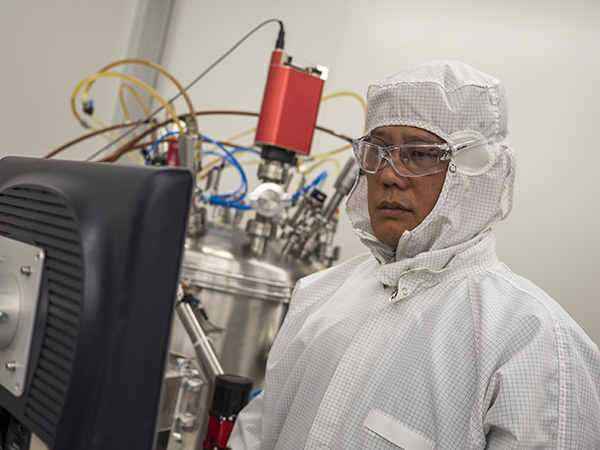

Recently, in their high-tech mobile studio set up ready for filming of the new Ron Howard biographical drama Thirteen Lives, they captured a high-fidelity model of Australian basketballer Maddison Rocci, using 90 cameras set up to capture different angles, in order to construct layers of detail in 3D.

Body scan data is then fed into a complex animation being developed by media producer Stefano Pizzolato of Naughty Monkey Studios, which combines the external data with a personalised biomechanical model of the internal mechanics of the body – effectively creating an exact digital twin of Maddison, both inside and out.

Griffith University Biomechanical Engineer Professor David Lloyd says the combination of big-budget film animation-quality, with their unique functional biomechanical model that both replicates and predicts stress and strain in the tissues inside the body, is a marriage made in heaven for elite athlete preparation.

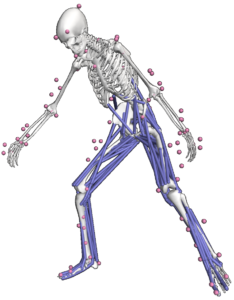

“We’ve built our proof of principal Digital Athlete utilising our platform technology – Personalised Digital Human – using 3D body scans, MRI and motion capture data so we have a really detailed representation of the body shape, bones, joints, muscles and other soft tissues in the daily performance environment,” Professor Lloyd says.

“The Digital Athlete allows us to understand the unique loading patterns on tissues in real time during performance, for example a side-step, which is both a common movement and cause of anterior cruciate ligament injuries in the knee.

This is critical, because each athlete will experience different stresses due to their unique physiology, which we are accurately capturing so we can prevent injury and optimise performance.”

Griffith Director of Sports Engagement and former Olympic rowing gold medallist Duncan Free is actively promoting the potential of the technology to sport officials, coaches and athletes and seeking to expand relationships with the AIS and QAS, while exciting other sporting bodies.

The Digital Athlete has the potential to be the ultimate coaching tool.”

“Coaches have a great eye for technique, but this can really take the guesswork out of designing training programs and be hugely valuable in helping to prevent injury and in rehabilitating athletes,” Duncan Free says.

For Duncan Jones, whose own innovation has seen him in constant work over two decades, the opportunity to collaborate on The Digital Athlete adds another string to his bow and has further convinced him of the value of university graduates who blend creative and scientific smarts.

“At Griffith they’re pushing boundaries, doing things that no-one else is doing,” he says.

“We’re jumping in to secure this new talent because if you don’t innovate with cutting-edge ideas and technologies you can’t make award-winning films nor adapt to the expanding opportunities in the post-Covid world of filmmaking – the Gold Coast is a leading location for filmmaking in the Southern Hemisphere and the future is exciting.”