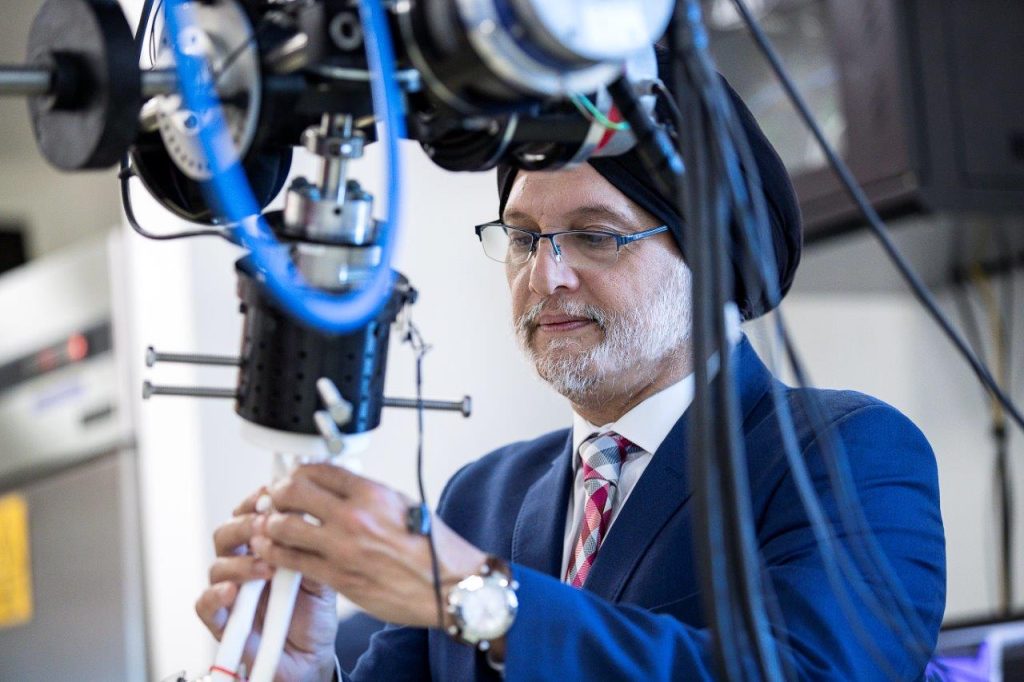

We offer a thriving entrepreneurial ecosystem of research, technology, industry and people working together to deliver meaningful impact.

From biomedical breakthroughs to advanced manufacturing and digital innovation, we bring together the expertise, facilities and support to develop, test and scale ideas that improve lives.