ADaPT is pushing the boundaries of next generation medical technologies to provide personalised surgeries, implants and devices, customised and intelligent neurorehabilitation for spinal cord injury and other conditions. Find out more.

Gold Coast Health & Knowledge Precinct

Transform with us

ADaPT to thrive

Industry 4.0 is the disruptive digital future of design and manufacturing, and additive manufacturing (AM) is a key enabler.

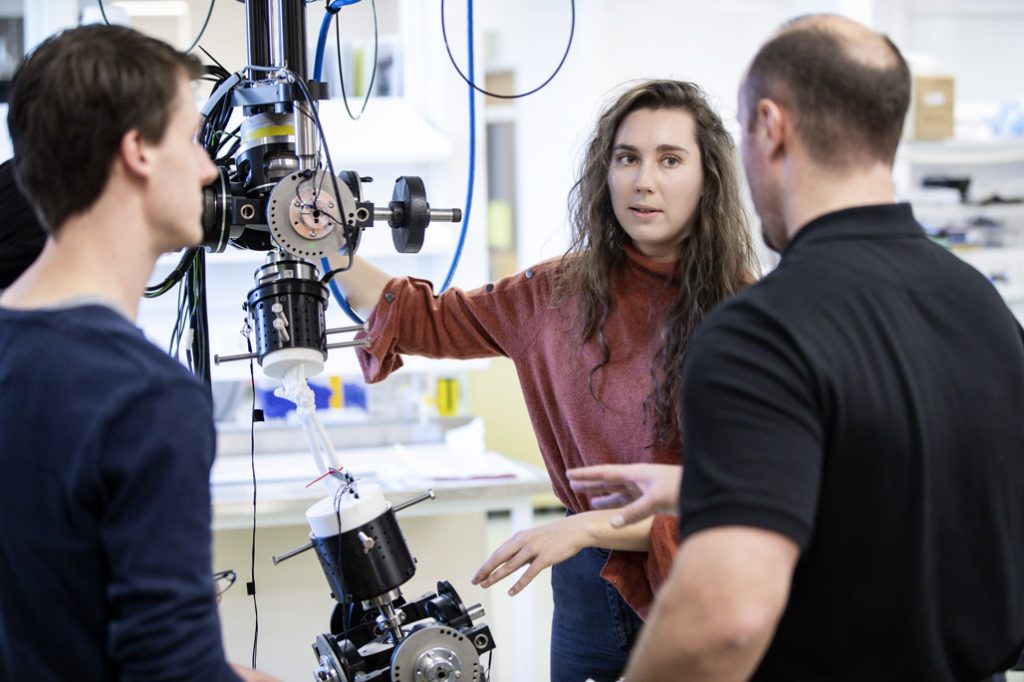

Griffith University’s Advanced Design and Prototyping Technologies Institute (ADaPT) brings together trans-disciplinary expertise across the university in collaboration with leading industry partners to push the boundaries in advanced custom design, rapid prototyping and exciting new materials, in what is called the ‘next industrial revolution’ or Industry 4.0.

Technology convergence bring business and healthcare opportunities

In the Industry 4.0 era the emerging trends of big data analytics and rising computer power, artificial intelligence and machine learning, the Internet of Things (IoT), advanced automation and robotics and advanced digital design, together with AM technologies, combine to create a super technology platform for ‘future factories’ and ‘smart hospitals’.

The digital world will completely represent and redesign the real world and exciting new materials and technology platforms will produce better, more customised products and more effective, personalised medical devices and treatments. As technologies and disciplines advance and converge, new business models will emerge and collaboration will be key.

Advanced Design and Prototyping Technologies Institute (ADaPT) - Medtech, GCHKP

Cost-effective, problem-solving

AM can open up new business opportunities through new product and service offerings, streamline existing manufacturing processes and save costs over the longer term.

For clinicians and healthcare providers, AM can help deliver cost-effective precision and personalised medicine.

AM solves problems and the first step doesn’t have to be complicated!

What is Additive Manufacturing?

Additive Manufucturing (AM) refers to a range of fabrication technologies incorporating 3D printing that produce new products and devices from the ‘ground up’. Traditional manufacturing processes are ‘subtractive’ – material is removed from a block until the product remains – from a sculptor chipping away at a block of stone to more advanced production processes including injection moulding. Additive manufacturing builds products ‘layer by layer’ and ‘version by version’.

Modern manufacturing uses computer aided design (CAD) and when combined with AM, it allows designers to accurately digitally model and test a physical product before manufacture, make small and cumulative changes that are reflected in the different printed layers of the design, then rapidly prototype the product using 3D printing.

AM allows for iterative, accurate, custom and personalised design with cost-effectiveness compared to traditional manufacturing methods.

This information paper, produced by Engineers Australia (National Committee for Rehabilitation Engineering), provides a good overview of AM technologies, their uses, advantages and limitations.

Case study - 3D printing aneuyrsm models for surgery planning and training

Utlising advanced images and specialist 3D design skills, Precinct experts are 3D printing exact replicas of an individual patient’s aneurysm in situ within the brain blood vessel so leading clinicians can better plan life-saving surgeries and train specialists from around the world in this precision specialised medicine.

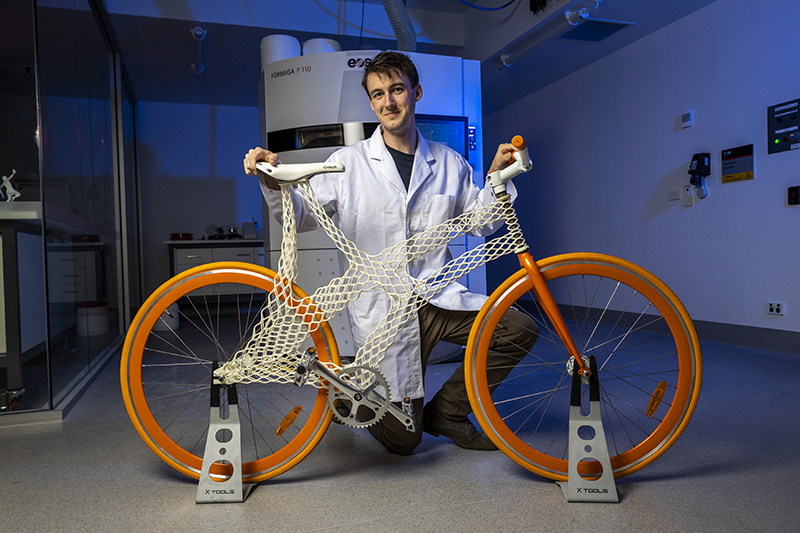

Bastion Cycles

Enthusiastic engineer and cyclist James Woolcock has combined his passions in a thriving bespoke bicycle business. At Bastion Cycles customers get to direct the design of their ultimate performance machine.

Renishaw

Renishaw are leading global manufacturers of precision equipment, including AM manufacturing equipment. ADaPT 1.0 hosts AM400: Queensland’s first industrial level metal Additive Manufacturing machine, capable of

producing medical grade implants.

Wrist rehabilitation

A multi-disciplinary team from Griffith University, Gold Coast University Hospital and industry is designing an artificial ligament, seeded with cells, to repair a common wrist injury.